Case Study Pennsylvania State University

Requirements:

- Reproducible growth conditions

- Low risk of contamination

- Optimal growth of cell cultures

- High process reliability

BINDER solutions:

- Reliable decontamination concept

- High level of temperature uniformity

- thanks to the VENTAIR air jacket system

- High relative humidity

- of up to 95% RH

- Stable pH values thanks to drift-free

- CO2/O2 IR sensor technology

The work of The Huck Institutes of the Life Sciences at the renowned Pennsylvania State University covers a wide range of applications in the fields of basic biomedical research and applied scientific investigation. The Huck Transgenic Mouse Core Facility at Pennsylvania State University specializes in embryonic stem (ES) cell research. Stem cell research has become increasingly important in fighting a whole host of diseases and even treating cancer. In fact, in the field of regenerative medicine in particular, this type of research is opening up unprecedented horizons. Stem cell therapy and transplantation can be used to repair or even replace dysfunctional cells and organs with the help of tissues grown in vitro.

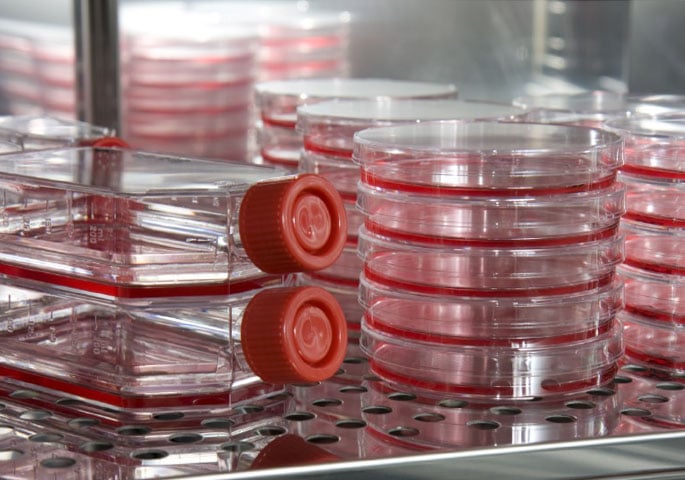

ES cells are essentially stem cells that are still in their early embryonic stage of development. Their infinite reproducibility and unrestricted differentiation potential makes them a versatile and virtually unlimited resource for replacing both cells and tissues. Basic research revolves around screening the development and regulation of early stem cell stages, as well as exploring the processes which underlie the ability of the cells to multiply and differentiate. The use of ES cells in clinical research offers the potential to successfully treat various illnesses including cardiovascular or neurodegenerative diseases.

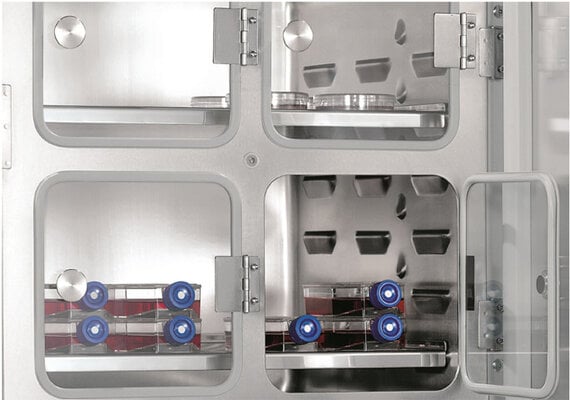

Embryonic stem cells and cell lines are cultivated in vitro. When it comes to working with cell cultures, sterile conditions and maximum safety are of the utmost importance. And this is precisely why the Institute made the decision to use CO2 incubators from BINDER. These units have a highly effective decontamination concept, with routine, hot-air sterilization at 180°C for absolute sterility. Right at the heart of the unit lies a fixed, heatsterilizable CO2 sensor. “Auto-sterilization reduces the risk of potential external contamination to a virtually non-existent level. This really is a key consideration when working with valuable human and mammalian cells,” explains Randall Rossi, Director of the Huck Transgenic Mouse Facility at Pennsylvania State University.

As cells are highly sensitive to their environment, uniform and reproducible growth conditions throughout the entire incubator chamber are essential for optimal cell cultivation. The VENTAIR™ air jacket system from BINDER guarantees uniform temperature distribution across all levels. What's more, the humidification system ensures a high level of humidity, providing optimal evaporation protection for cultures. The rapid humidity recovery times minimize the likelihood of cell degradation when opening the door. Randall is a particular fan of the drift-free CO2 measuring system with infrared sensor technology. The gas mixing jet based on the Venturi principle offers uniform CO2 gas distribution, which not only stabilizes the pH value in the medium in the long term, but also guarantees optimal cell growth.

“I have been working with BINDER incubators for around 15 years now and have always been totally satisfied with both the functionality and services. They are 100 percent reliable and offer the best incubation properties thanks to their constant temperature and humidity conditions,” explains the scientist in his overall verdict on the units.

Advantages

- Patented chamber design for maximum sample safety

- Hot-air sterilization at 180 °C

- Sterilizable CO2 sensor

- Unique BINDER technologies (patented air jacket system, controlled condensation, etc.)

Application

- Biotechnology

- Bio-tissue engineering

- Clinics / university hospitals