Tasks and objectives:

- Load tests of vehicle components

- Test procedures in accordance with test standards

- Resistance to aging and lifetime of painted and coated parts

- Determination of durability, peeling, crack formation, and changes to the degree of color and gloss

- Heat aging to test temperature resistance

- Optimal process reliability

- Precision and reliability

BINDER solutions:

- MKF dynamic climate chamber

- Temperature range: -40°C to 180°C

- Humidity range: 10 to 98% RH

- Cyclical alternating climate tests

- Standardized tests

- Complex temperature profiles

- ED drying chamber

- Wide temperature range from 5°C above ambient temperature to 300°C

- High temperature accuracy

In the test laboratory of Lothar Bix GmbH in Messkirch, painted and coated automotive components are subjected to stringent tests

In the test laboratory of Lothar Bix GmbH in the German town of Meßkirch, painted and coated vehicle components are subjected to rigorous tests. Searing heat, Siberian cold, tropical humidity, or simply just wind and rain – most vehicle

components come into contact with a wide range of environmental influences throughout their lifetime that impair their function and/ or appearance, and therefore cut short their operating life. During daily use, they are also frequently exposed to severe mechanical loads and have to be able to function safely and reliably even under extreme conditions.

The various vehicle parts and materials are therefore subjected to demanding load tests to determine their resistance to climatic influences and temperature. For automotive suppliers, the ever-increasing requirements and warranty periods represent a real challenge. What’s more, many companies have established their own test standards. Automotive manufacturers of painted and coated components have also developed a whole host of special test procedures. Nearly all plastic parts inside the vehicle are now painted.

Testing the durability of paint finishes

Lothar Bix GmbH from Meßkirch specializes in innovative coating methods and high-quality paint finishes. In order to test the durability and resilience of paint finishes or coatings, the company performs an extremely wide range of environmental simulation tests in its in-house test laboratory for customers from the automotive industry. The tests are run in accordance with OEM regulations and international standards such as VW TL 226 and Daimler DBL 7384. In constant climate chambers and drying chambers from BINDER, the painted or coated parts are tested in terms of various criteria: temperature and weather resistance, lifetime in various temperature ranges and climatic zones, as well as resistance to aging. Interactions with various media, such as sweat, sun cream, or care and cleaning products, are also determined. This enables potential damage, such as negative effects on gloss and color effects, or paint adhesion problems, to be identified at an early stage. The aim of the environmental simulations is to discover weak points in products quickly and effectively and to avoid complaints.

Heat aging

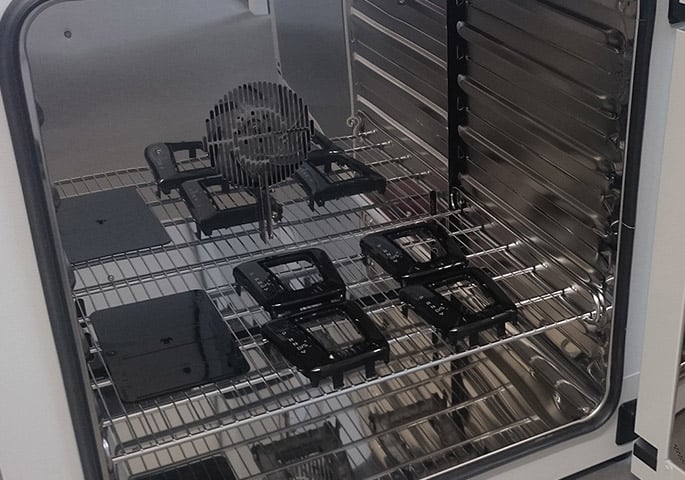

BINDER drying chambers from the ED series are used for heat aging and to test temperature resistance. The units have a wide temperature range from 5°C above ambient temperature to 300°C. Based on the high temperatures, the behavior of the test parts can be determined with respect to durability, peeling, crack formation, and changes to the degree of color and gloss.

Alternating climate tests

In dynamic climate chambers from the MKF series , the painted and coated parts are tested under dynamic conditions. Complex dynamic climate profiles are run with a temperature range of -40°C to 120°C, a humidity range of 10% RH to 98% RH, and a storage period of up to 30 days. Cyclical alternating climate tests or even accelerated short-term tests involving time lapse are used to determine the lifetime of the test specimens at 90°C / 96% RH over 3 to 7 days, and their resistance to aging under fluctuating environmental influences is characterized. The temperatures and duration of a climate test are adapted to the conditions under which the product is used and its life expectancy. Wolfgang Scherer, Head of Quality Assurance / QMO at Bix, explains why the company opted for simulation chambers from BINDER.

“The large interior with a volume of over 720 liters is perfect for us to also test complete components. As we work using reproducible methods, constant test conditions in the test room as well as absolute precision and reliability are also extremely important. BINDER is the perfect match for us.” There was also another bonus: “As we paint the housings of BINDER chambers, we have already established an excellent working relationship over the years and value the good customer service we receive. So it was an obvious choice for us to opt for BINDER simulation chambers,” concludes Mr. Scherer. Since 2013, Bix has been providing coatings for BINDER on a fully automated robotic powder coating facility.

This was designed in line with BINDER’s needs to enable even the largest housings to be coated.

The company Bix

The company Bix was founded in 1887. Over the course of the company’s 130-year history, its work has spanned everything from gilding, painting, and providing the finishes on horse-drawn carriages, right the way up to today’s highly automated industrial coating technology.

The advantages of the MKF dynamic climate chamber:

- Heated viewing window with LED interior lighting

- Programmable condensation protection for test material

- Integrated water-storage tank, 20 L (model 115, 240, 720)

- Constant test conditions

- High quality and reliability