Safe Battery Test Chambers

for Testing Lithium-Ion Cells, Modules, and Systems

Our innovative battery test chambers are specifically designed for testing lithium-ion cells and modules. Battery tests are complex and require the highest safety standards to minimize potential hazards.

Handling lithium-ion batteries involves various risks, ranging from overheating to chemical reactions. Therefore, it is crucial for test facility operators to carefully assess these risks and implement a well-thought-out safety concept. With BINDER by your side, you are well-equipped to meet these challenges.

Discover how our solutions can help you test safely while ensuring compliance with all relevant regulations.

Your Advantages

Our Product Solutions for reliable test environments

Safe classification and handling of energy storage devices is a key factor in conducting reliable battery tests. The basis for this is the EUCAR Hazard Level – a scale developed by the European Council for Automotive R&D for the systematic assessment of potential battery hazards. Naturally, our test environments meet all relevant industry standards such as DIN EN IEC and ISO.

Based on these hazard levels, BINDER has developed modular safety packages, designed for EUCAR Levels 0 to 6, which integrate seamlessly into BINDER temperature and climate chambers. Combinations with various models and sizes are possible. We also implement custom project-based solutions – for maximum safety and reliability in every test.

| Equipment | Package A EUCAR 0-2 | Package P EUCAR 0-4 | Package P+ EUCAR 0-5 | Package G EUCAR 0-5 | Package S EUCAR 0-6 |

|---|---|---|---|---|---|

| Temperature limitation for the unit | |||||

| Class 2 | |||||

| Door bracket | – | ||||

| Pressure relief flap (150 mm) | – | ||||

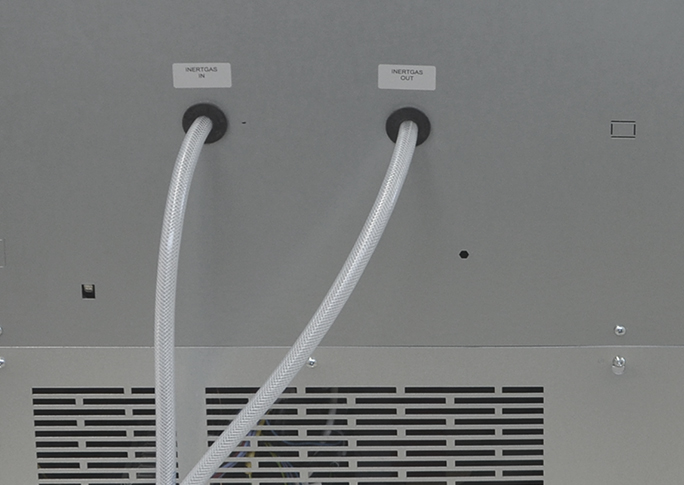

| Inert gas connection (unregulated) | – | – | |||

| Temperature detection | – | – | |||

| Manual trigger | – | – | |||

| Connection for CO₂ cooling and flushing system | – | – | |||

| Single-color alarm signal light | – | – | – | – | |

| Three-color warning/alarm signal light | – | – | – | ||

| Gas detection CO | – | – | – | ||

| Gas detection H2 | – | – | – | – | |

| Gas detection O2 | – | – | – | – | |

| Inertization equipment (regulated) (Event-controlled → Flushing) |

– | – | – | – | |

| Electromechanical door-locking mechanism | – | – | – | ||

| Optional | |||||

| Additional flexible temperature sensor (Limit value overshoot → CO2 trigger) |

– | – | |||

| Electromechanical door-locking mechanism | – | – | |||

| Pressure relief flap (200 mm) | – | ||||

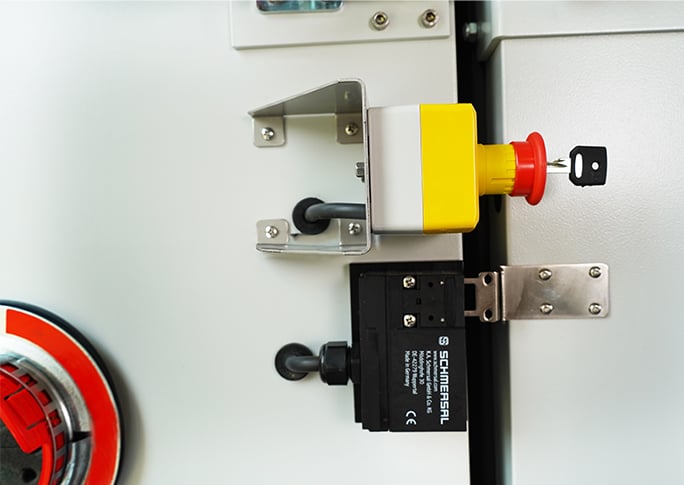

| Emergency stop | |||||

Aging Tests – Package A

The Package A safety system is suitable for aging tests of unpowered energy storage devices at Hazard Levels 0 to 2.

Standard equipment:

- Temperature range: -70 °C to +120 °C

- Temperature limiter up to 120 °C integrated into the unit

- Independent, intrinsically safe temperature limiter (Class 2) pre-set to 120 °C

Optional equipment:

- Electromechanical door lock

- Emergency stop push button

Performance Tests – Package P

This safety package P is suitable for aging and performance tests of energy storage devices up to Hazard Level 4.

Standard equipment:

- Temperature range: -70 °C to +120 °C

- Independent, intrinsically safe temperature limiter (Class 2) pre-set to 120 °C

- Enhanced mechanical door locking system with two reinforced latches

- Reversible pressure relief flap (diameter 150 mm) with connection (diameter 250 mm)

- Inert gas connection (non-controlled)

Optional equipment:

- Electromechanical door lock

- Emergency stop push button

- Overpressure relief flap (200 mm)

Extended Performance Tests – Package P Plus

The Package P Plus is tailored for aging and advanced performance testing of energy storage devices up to Hazard Level 5.

Standard equipment:

- Temperature range: -70 °C to +110 °C

- Independent, intrinsically safe temperature limiter (Class 2), pre-set to 120 °C

- Enhanced mechanical door locking system with two reinforced latches

- Reversible pressure relief flap (diameter 150 mm) with connection (diameter 250 mm)

- Inert gas connection (non-controlled)

- Connection for CO₂ cooling and flushing system

- Additional independent temperature detection – activates CO₂ cooling and flushing system at 120 °C

- Manual activation of CO₂ cooling and flushing system

- Acoustic and visual alarm

Optional equipment:

- Electromechanical door lock

- Emergency stop push button

- Overpressure relief flap (200 mm)

- Flexible temperature sensor, triggers CO₂ cooling and flushing system when limit is exceeded

Extended Performance Tests – Package G

Package G includes additional safety features with enhanced sensor technology and is suitable for aging and extended performance testing of energy storage devices up to Hazard Level 5.

Standard equipment:

- Temperature range: -70 °C to +110 °C

- Independent, intrinsically safe temperature limiter (Class 2) pre-set to 120 °C

- Enhanced mechanical door locking system with two reinforced latches

- Reversible pressure relief flap (diameter 150 mm) with connection (diameter 250 mm)

- Inert gas connection (non-controlled)

- Connection for CO₂ cooling and flushing system

- Additional independent temperature detection – activates CO₂ cooling and flushing system at 120 °C

- Manual activation of CO₂ cooling and flushing system

- Tri-color warning/alarm signal light with acoustic signal

- Electromechanical door lock

- Gas detection with CO sensor – triggers CO₂ cooling and flushing system

Optional equipment:

- Emergency stop push button

- Overpressure relief flap (200 mm)

- Flexible temperature sensor, triggers CO₂ cooling and flushing system when limit is exceeded

Stress Tests – Package S

This extensively equipped safety package is designed for testing lithium-ion batteries and fully supports EUCAR Hazard Level 6.

Standard equipment:

- Temperature range: -70 °C to +110 °C

- Independent, intrinsically safe temperature limiter (Class 2), pre-set to 120 °C

- Enhanced mechanical door locking system with two reinforced latches

- Reversible pressure relief flap (diameter 150 mm) with connection (diameter 250 mm)

- Inert gas connection (non-controlled)

- Connection for CO₂ cooling and flushing system

- Additional independent temperature detection – activates CO₂ cooling and flushing system at 120 °C

- Manual activation of CO₂ cooling and flushing system

- Tri-color warning/alarm signal light with acoustic signal

- Electromechanical door lock

- Gas detection using H₂, CO, and O₂ sensors – activates CO₂ cooling and flushing system

- Controlled inerting system

Optional equipment:

- Emergency stop push button

- Overpressure relief flap (200 mm)

- Flexible temperature sensor, triggers CO₂ cooling and flushing system when limit is exceeded

BINDER Customized Solutions

Looking for tailored solutions for your battery testing? BINDER Customized Solutions supports your project from consultation to implementation.

Cycler Chamber Chiller

BINDER battery test chambers are compatible with third-party devices from all manufacturers.

Click here to learn more about Turnkey Solutions for Battery Testing.

Frequently asked questions

BINDER battery test chambers are suitable for testing lithium-ion cells, modules, and battery systems. They are used to test aging, performance, and stress in research & development, quality assurance, and production.

The chambers comply with relevant norms and industry standards including DIN EN EC, IEC, and ISO. They are also suitable for battery testing in accordance with EUCAR Hazard Levels up to Hazard Level 6 (EUCAR Hazard Level 6).

The most important safety functions include:

- Independent temperature limitation (Class 2)

- Reversible pressure relief flap

- Mechanical door-locking function with two reinforced clamps

- Inert gas connection

- Gas detection (CO, H₂, O₂)

- Acoustic and visual alarms

- Electromechanical door-locking mechanism

Yes, BINDER offers customized solutions. Every battery test chamber is built from a series production unit and an equipment package in accordance with customer requirements. BINDER Customized Solutions even offers an option to configure an entirely individual unit from scratch.

BINDER battery test chambers are compatible with all cyclers and chillers, regardless of manufacturer, and are flexible for integration into existing test environments.

The temperature range depends on which series production unit the chamber is based on. BINDER refrigerated incubators, which are often used as temperature test chambers, cover temperature ranges from -20°C to +100°C, for example. Dynamic climate chambers are available for temperature ranges from -70°C bis +180°C. Temperature limitation is determined by the safety packages. Package A and Package P -70°C to 120°C and Package P Plus, Package G, Package S -70°C to 110°C.

The possible combinations are always dependent on by prevailing customer requirements. Every battery test chamber configuration starts with a feasibility check, during which we examine and specify individual customer requirements, then recommend a series production unit based on our findings.

Lead times depend on the scope of the order. Please also bear in mind that lead times can also be affected by the distance to be traveled to reach the intended delivery destination.

BINDER Battery Test Chambers

Battery test chambers can be customized to your specific requirements and equipped with additional functionalities. Have questions? Our expert team is happy to assist!