Case Study MinebeaMitsumi Technology Center Europe GmbH

Remit Dynamic climate chambers:

- Reliable and precise

- Wide temperature range

- Humidity

- Even climate conditions

- Internal data logger, measured values can be read out in open format via USB

- Door heating

- Unit with casters, easy to transport

BINDER solutions:

- Temperature range: -40 °C to 180°C

- Humidity range: 10% to 98% RH

- Integrated water-storage tank, 20 L

- 4 zero-voltage relay contacts

- APT.line™ preheating chamber technology

- Programmable condensation protection for test material

- Heated viewing window with LED interior lighting

MinebeaMitsumi Technology Center Europe GmbH, which is based in Villingen-Schwenningen in southern Germany, is the international MinebeaMitsumi Group’s largest motor development center. It is the only center of its kind in Europe and employs over 400 staff. Visitors are immediately impressed – you’ll find development labs, test labs, a large clean room and a special test room containing over 80 BINDER chambers. The motors produced here in the city of two halves are secured to a base plate and have to be tested multiple times before going to production. After all, customers are guaranteed a minimum service life of five years, an aspect that Stefan Vogtel, the head of the service life testing and fault analysis department, tests on a recurrent basis using drying chambers, cooling incubators, dynamic climate chambers and constant climate chambers by BINDER. A service life of five years can be simulated in no more than six months. And, as the department head explains, end-of-life testing is now becoming increasingly important as well. The focus of this process – as the name reflects – is to look at the actual service life of MinebeaMitsumi motors.Do this, the company uses equipment such as dynamic climate chambers by BINDER, MKFs in the size 240.

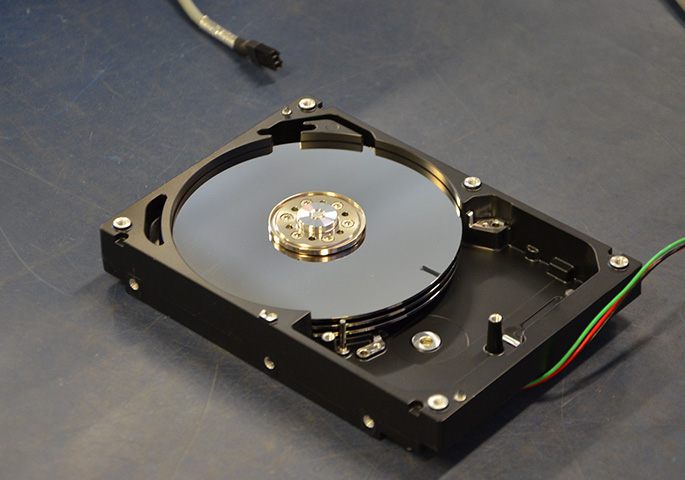

Stefan Vogtel says: “It is a great oven. It does exactly what it is supposed to and is 100% reliable.” Some background information: the hard drive motors no longer have any ball bearings but are equipped with fluid dynamic bearings

(FDB) instead. They are tested between roughly minus ten and +100°C and at 85% relative humidity. And the MKF 240 masters all of this with ease. The dynamic climate chamber is one of the most popular ovens in the department. Vogtel adds: “Nowadays, tests are becoming increasingly specific, which means that the BINDER chambers we use have to meet stricter or changing requirements. For instance, the company can’t really manage without access ports these days, which are mainly implemented by BINDER INDIVIDUAL. An FED 720 drying chamber, for example, is ideally suited to this job. And Vogtel has not one but many versions of this type of chamber in use.

They are located next to whole racks full of electronics, each of which always controls one motor in the chamber’s interior. “A total of 120 running motors can therefore fit in one chamber, for instance, and can be subjected to up to 130°C”, explains the expert from the Japanese corporation. The KMF 720 constant climate chamber and KB 720 cooling incubator are also used in the measurement room for conducting service life tests and analyzing faults. Here, BINDER chambers run permanently at a wide range of temperatures, and department head Vogtel is particularly impressed by the high interior volume of the individual chambers. “They can hold so many products and are easy to use,” explains the specialist. Reliability is important to Vogtel in general, as a large number of samples are taken and required to ensure that the five to seven billion motors produced by MinebeaMitsumi every month are of perfect quality.