BINDER INDIVIDUAL

Individual extras for your simulation chamber

What is BINDER INDIVIDuAL?

Individual solutions to meet your unique requirements

In our BINDER INDIVIDUAL department at the Tuttlingen plant, we turn your unique requirements into reality. Be it stainless steel housing, special access ports, O₂ control or much more, we use a proven series production product to create your customized solution. This solution is developed by our experts and manufactured as a single unit or in small series production.

Request now

BINDER series production device

Series production products offer guaranteed premium quality.

BINDER series production device & optional series production equipment

With accessories and equipment options, series production products can be optimized for popular requirements profiles.

BINDER INDIVIDUAL

Highly specialized individual solutions are the result of the custom modification and enhancement of series production devices.

Request

Your request is sent to us either directly or through a trade partner.

Examples of BINDER INDIVIDUAL solutions

Dynamic climate chamber

with hand access ports

Model MKT 115

Requirements

- Testing of rubber samples

- Work on the test material with the door closed

- Access ports with removable gloven

- Sealable openings

Solution

- Glass door

- 2 stainless steel hand access ports with glove attachment DN 140

- 2 silicone sealing plugs

- 1 pair of dry-box gloves made from neoprene

- 1 cover for hand access port area

- Simple removal of gloves

Added value

- Hand access ports enable work to be carried out on test material when door is closed

- Climate in the chamber and at the test objects remains unaffected

- Thanks to removable gloves and sealable openings, the full temperature range of the chamber can be utilized

Drying and heating chamber

with stainless steel housing

Modell FED 400

Requirements

- Complete stainless steel version to meet strict hygiene standards of food industr

Solution

- Stainless steel housing 1.4301

Added value

- Compliance with hygiene standards of the food industry

- Excellent corrosion protection

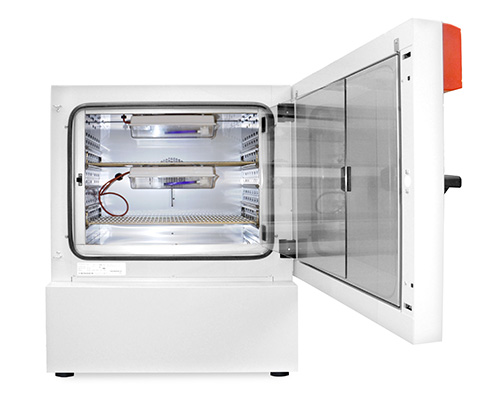

Cooling incubator

with special light

Modell KB 115

Requirements

- Version of a 115-liter device with illumination cassettes for various light spectrums: black light, daylight

- Space-saving mounting of lamps

- Illumination on 2 shelf levels

Solution

- Two 9 W lamps

- One lamp integrated into the ceiling

- Second illumination cassette mounted under the shelf to save space

- G 23 socket for all commercial lamps

- On/off switch on control panel

Added value

- Light test possible in small device

- Test objects can be illuminated on two shelves at the same time

- Shelf height remains variable

Constant climate chamber

with 4 light sensors

Modell KBF LQC 720

Requirements

- Precise measurements with equal light quantities on each level

- 1 sensor under each illumination cassette

- Total of 4 illumination cassettes with sensor

Solution

- 4 VIS sensors in total, 1 sensor per level

- Second controller for visualizing light quantity on additional levels

- Fourth illumination cassette with separate power supply

Added value

- Measurement with exact light dosage for each level

Material test chamber

with status indication

Modell M 400

Requirements

- Clear display of process progress

- Process must not be interrupted when door is opened

- Functions should be programmable

- Acoustic feedback

Solution

- LED signal lights

- Programmable control contacts

- Electromechanical door-locking mechanism

- Lockable controller with key

- Acoustic signal via buzzer

Added value

- Reliable testing

- Central monitoring of fault indications and temperature sensors

- Reproducible test results