Tasks and objectives:

- Stress tests under the effects of heat and humidity

- Accelerated aging process

- Constant conditions and factors over a long period of time

- Long-term tests

BINDER solutions:

- KBF constant climate chamber

- Temperature range 0°C to 70°C

- Humidity range 10% to 80%

- Humidity regulation with capacitive humidity sensor and steam humidification

- Inner chamber made completely of stainless steel

- Two racks made of stainless steel

- APT.line™ preheating chamber technology

In the medical sector, products need to be absolutely safe

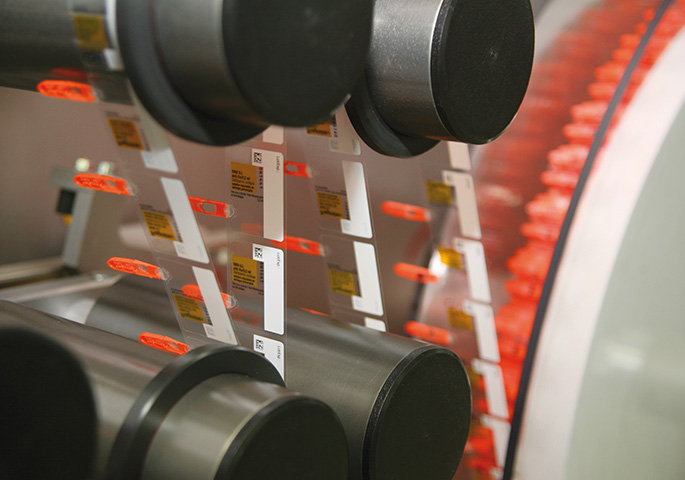

The Schreiner Group in Oberschleißheim, Germany specializes in developing and producing innovative functional labels. However, the company, based in the greater Munich area, also has all sorts of products in its range.

For example, it also makes compensating membrane films, which are used in the automotive sector – or, more specifically, in the engine bay. This product should let air through, but not dirt and water. The film must also be heat-resistant. It is very much a quality product, which has to prove its abilities again and again – not just in practice but also in the Schreiner Group's own research and development lab. For this test, 20 BINDER heating chambers are available.

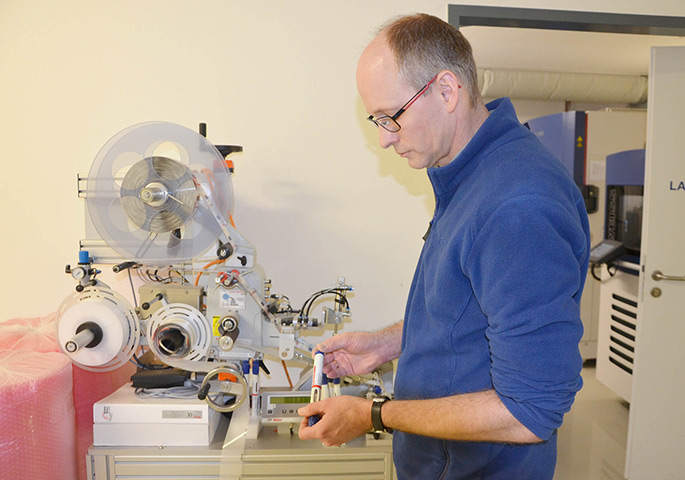

Laboratory team leader Markus Rübekeil raises the temperature of these up to 150°C and places the film inside for an

hour. These are then removed and placed in a water basin at two degrees for five minutes. It is a real stress test, which extends over ten cycles. “The heating chamber can achieve a high temperature, is precise and runs continuously. Lots of our ovens have been running for years,” explains Markus Rübekeil.

Using climate chambers

The Schreiner Group is also known for developing special labels for the pharmaceutical industry. The markings on injections, for example, need to be able to withstand factors such as heat, cold, and liquid. To show that the labels themselves can still be read, even if extreme situations like this occur, the laboratory team leader uses BINDER climate chambers. The testing elements – in other words, labels with parts of documentation – are stored over a long period of time at 40°C and 85% relative humidity and demonstrate their resilience. “In the medical sector in particular, products need to be absolutely reliable and we are proving this with BINDER chambers in the lab,” the expert states. The labels are also put in a freezer at -80°C. And if they still stick after they have been stored, then they are suitable for use in practice. The particularly innovative label from Schreiner also features a needle trap. This product is manufactured at the company headquarters in Oberschleißheim and is regularly tested using one of the climate chambers on site. It provides safety for patients in practice if they need to inject themselves.

An infusion hanger can also be found on the label and comes from the Schreiner Group. The laboratory team leader also tests this on a regular basis. The Bavarian family-run company also produces the non-woven part of an airbag,

an adhesive strip on which a label can be found. The small, but extremely important, part of the airbag must be

regularly subjected to heat tests in the lab. In the summer, it can get extremely hot inside a car and it is important that

this does not trigger an airbag or cause damage to it. With the help of the BINDER heating chambers, the product can be subjected to extreme heat. And the material is only used in practice and by the general public when it passes this test in a BINDER chamber.

Advantages of constant climate chambers

- Homogeneous climate conditions thanks to APT.line™ preheating chamber

- Automatic water and waste water management

- Responsive steam humidification

- Internal data logger

Areas of application:

- Pharmacy

- Automotive

- Printing and packaging industry